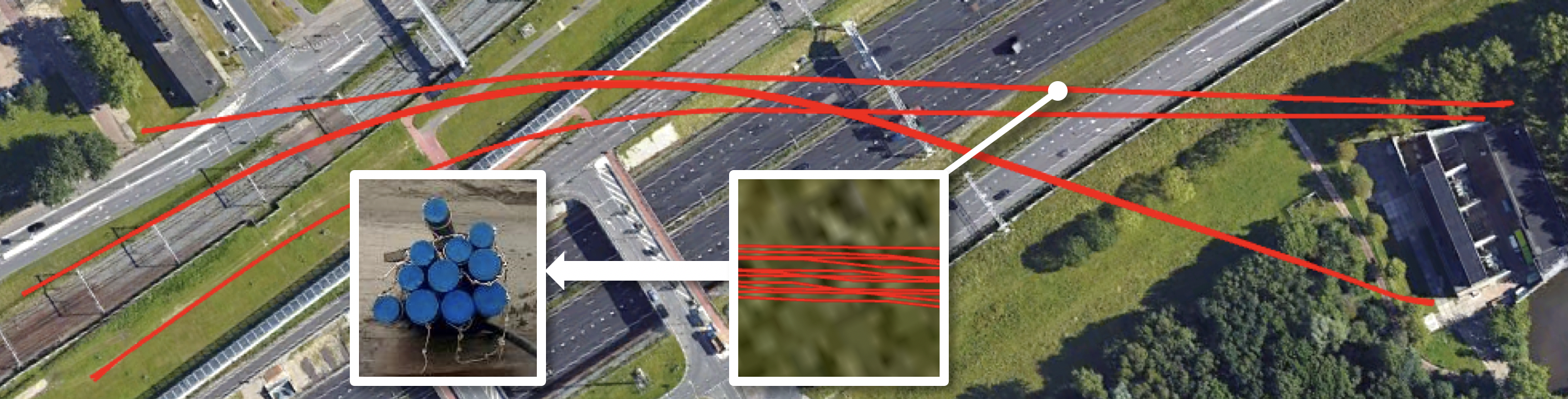

Case Study 3

Mapping an entire HDD bundle to reduce risk

In preparation of the roll-out of a new fly-over complex, three bundles of 11 ducts each were installed by means of HDD. Despite laying about 43m/140ft below the surface, the electricity utility owner was concerned that future ground works would damage a duct or bundle on this highly critical route.

When mapping just one duct in a bundle, nothing is known about the location of the other ducts in that bundle, so they can be positioned anywhere around the mapped duct. This would necessitate a significant safety zone around the measurement result of the single mapped duct. Therefore, all ducts were mapped to get a more accurate picture of the position of the entire bundle and thus reduce the risk of damage during the fly-over build phase.

The field crew followed the recommended standard operational procedure and mapped each duct four times (so-called FBBF method). The crew achieved a productivity of 11 pipes per day, or well over 5.5km / 18.000ft.

The fly-over complex was completed without any damage to the bundles.