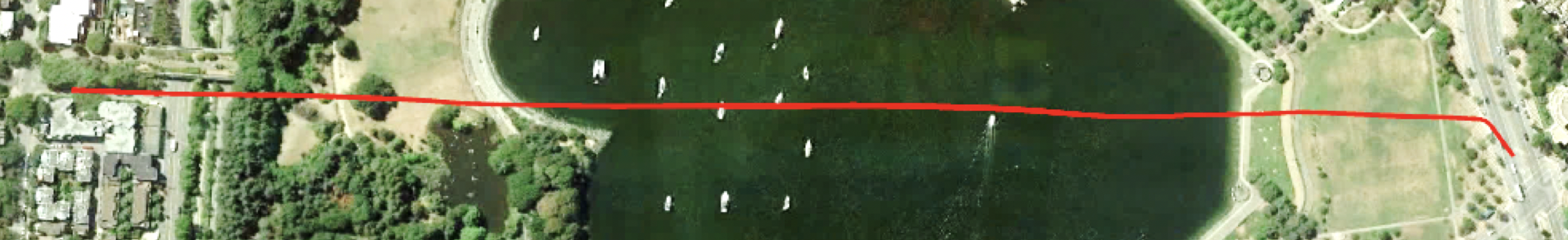

Case Study 9

Assessing torque of a bundle of ducts

A power utility had pulled in a bundle of 6 ducts for future HV power cables. The engineers were worried that the bundle had torqued (twisted) during the pull because torque increases drag, thus potentially exceeding the cables maximum tensile strength.

To understand the behavior of the bundle the survey crew mapped 4 ducts in one afternoon. The resulting profiles were loaded into a 3D modeling software that enable the user to ‘fly over’ the result. Below several screen shots of the fly-over projection.

Most important to note is that along the bore there is no sign of excessive torque. The bundle gradually rotates approximately 180 degrees as it passes the deepest point, but that is a very gradual rotation and has no notable impact on pulling tension. This conclusion is confirmed by the standard bend radius calculation feature in the system software. The client did not need to invest in a stronger cable. Each pipe was mapped twice, which means productivity for the afternoon was 3.9km /12.820ft.