Case Study 8

Determining the location of damage to a pipe

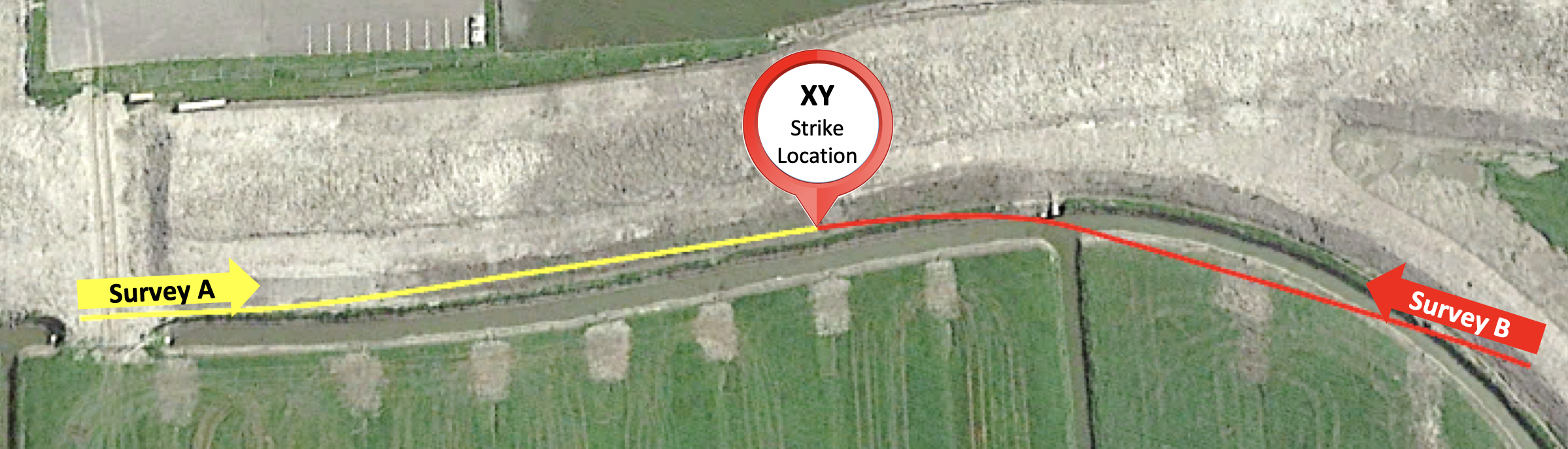

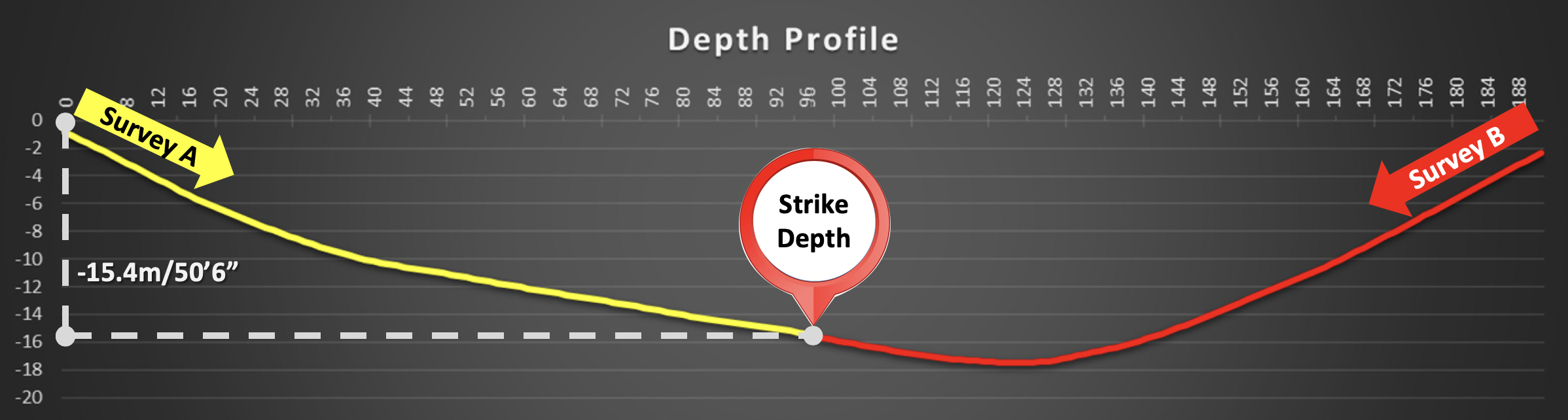

An exisiting pipe near a new road development failed the roundness calibration test after the road was completed. The deformation proved so severe that the survey probe could not pass the damaged point. Therefore, two single-entry surveys (A and B) were conducted, starting at the nearest access points on each side of the damage. The two survey results were merged in AutoCAD to determine the exact strike location.

The measurement results clearly identified the cause of the damage and the results were used in the insurance claim.